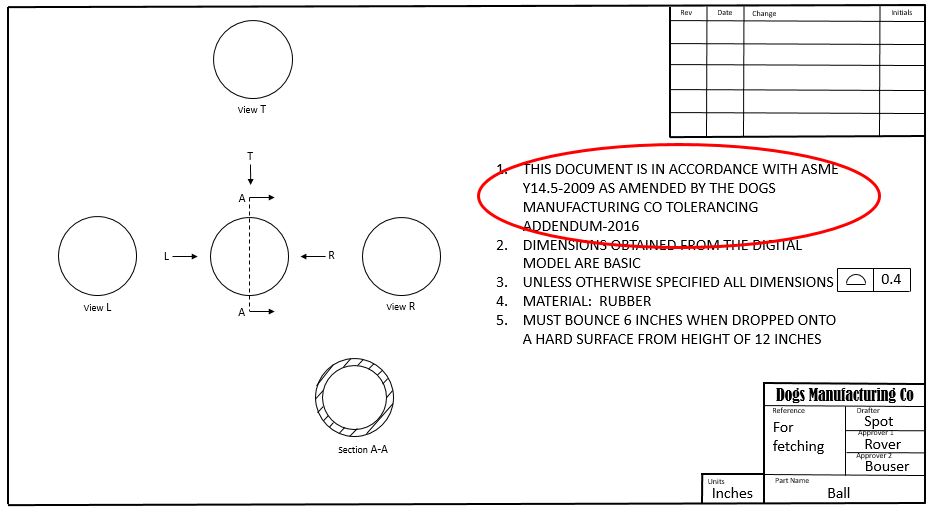

These symbols have been able to replace the traditional handwritten notes and ensure a standard approach to dimensioning and tolerancing that is friendly to the manufacturing & inspection world. To do all of this, GD&T utilizes a set of standard symbols to describe the different features or requirements of a component. Today, the GD&T methodology provides a robust method to communicate all of necessary information associated with a component which include dimensions, tolerances, geometry, materials, finish and all other pieces of information about a drawing (revision, part number, etc). The GD&T methodology was created to standardize the “language” of engineering drawings, so that no matter who you are, or where you were in the world, you could read a drawing and understand exactly what is required for that component. These handwritten notes became a source of error as organizations began scaling up or when those notes needed to be translated to other languages. To ensure that your engineering drawings are communicated effectively (error-free), drawing creators (designers) use a technical “communication language” called GD&T or Geometric Dimensioning & Tolerancing.īefore the development of GD&T, traditional engineering drawings often contained many handwritten notes to capture the designers intent.

This includes process designers, component buyers, component suppliers, raw material inspectors, assemblers, post-assembly QC inspectors & lastly the customers themselves.

The next benefit or purpose of the engineering drawing is to act as a communication tool.Īs a Quality Engineer you’re likely aware that there are many different people within the manufacturing process who will need information about the new components or assemblies that have been designed. One of the most important is to capture the intention of the designer and all of the requirements associated with the newly designed product. These Engineering or Technical Drawings serve a number of different purposes. In the last chapter ( Design Inputs & Reviews), we covered the three phases of product design which often result in the creation of detailed engineering drawings associated with your new product.

0 kommentar(er)

0 kommentar(er)